Product Overview

Ozone decomposition

Ozone is an enormously powerful molecule, useful for applications both in air and water treatment. After the ozone treatment process, residual high concentrations of ozone may still be present. When unwanted, this requires ozone destruction. Acniti developed a modular ozone destruction solution based on a catalysator which is scalable for small to large applications.

In research applications, producing ozone off-gassing, a small ozone decomposer will be sufficient. For large ozone contact tanks where it is not practical to release ozone into the atmosphere or reintroduce it into the water, a larger ozone destructor is required.

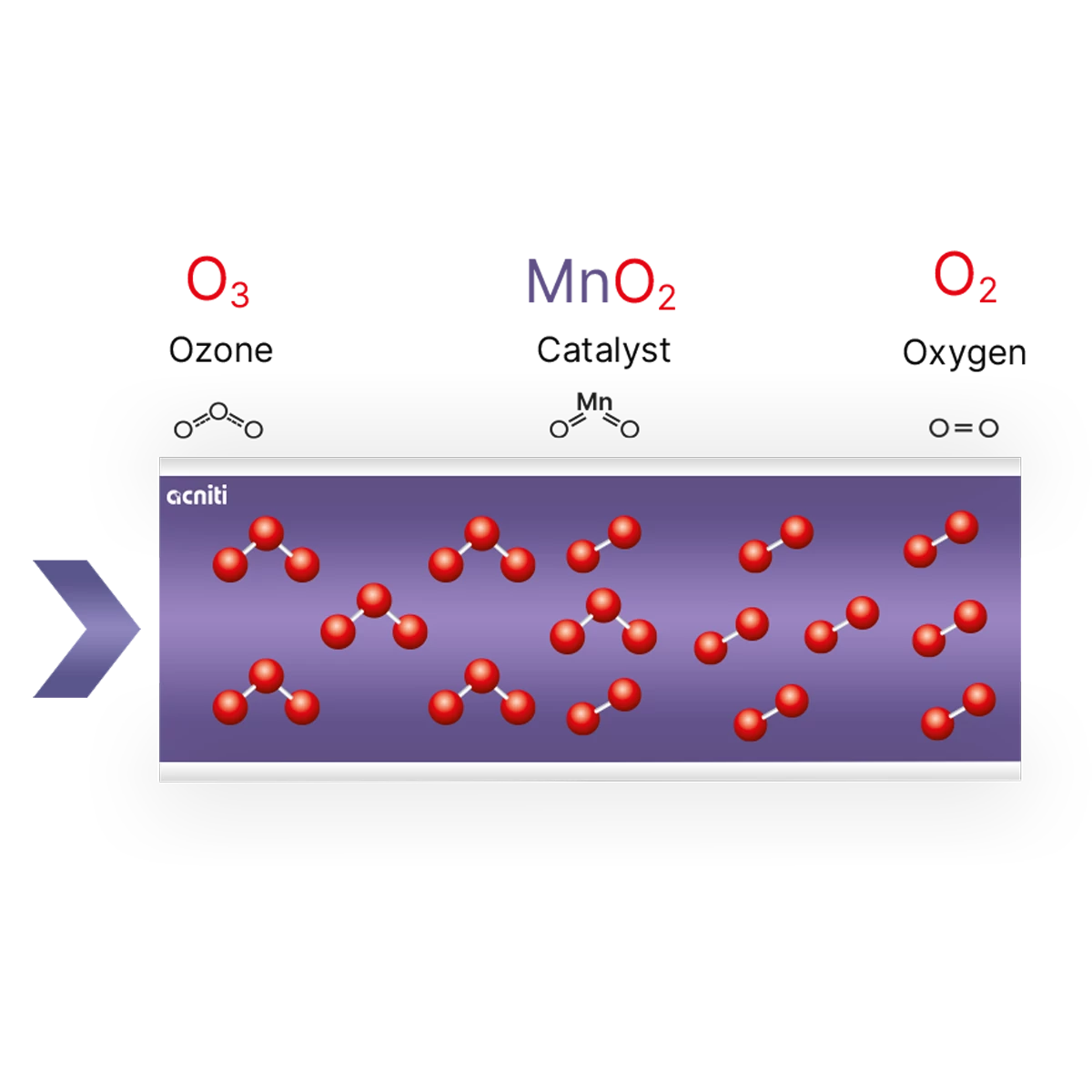

The acniti ozone decomposer uses a catalytic method to remove excess ozone. The catalyst is a transitional metal, manganese dioxide, in combination with palladium. The benefit of using a catalyst is that ozone does not consume the catalyst. Ozone destruction or decomposition occurs in a catalyst sieve, where ozone is converted to pure oxygen by the catalyst.

Modular ozone destruction

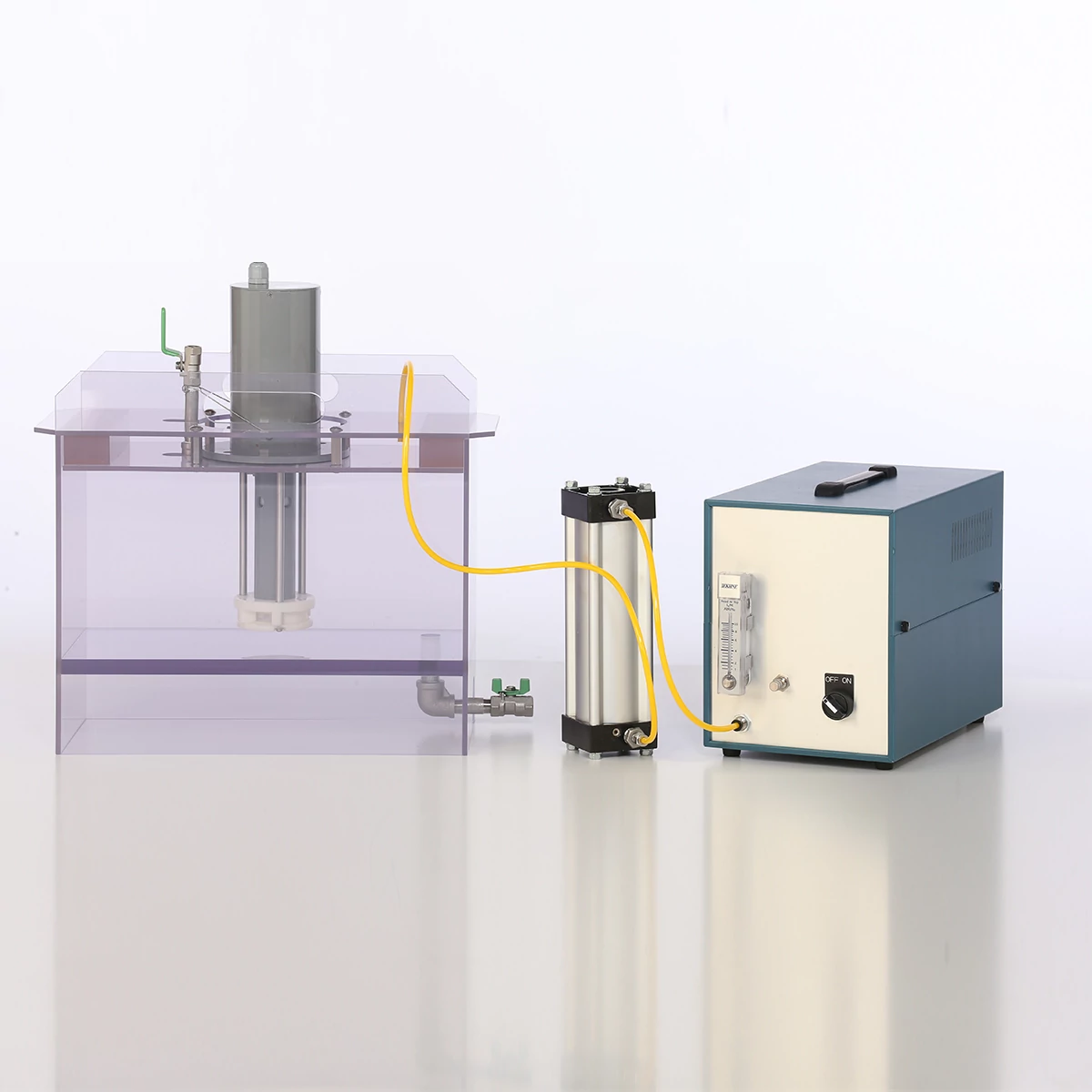

To put ozone destruction into practice acniti has developed a modular system consisting of four steps. Step 3 is the core step of ozone destruction. The design of the other three steps is to protect the equipment and the catalyst. These additional steps are optional, depending on the destruction application:

Acniti modular ozone decomposer:

The water-trap

Using the ozone destructor application with the risk of water entering the system, acniti recommends the water trap. In the event water is entering the system, the water trap will drain the water and protect the catalyst sieve en vacuum pump from getting wet.

Heated chamber

When the humidity of the gas is higher than 75% acniti recommends a heater chamber; humidity higher than 85% requires the heater chamber. When the catalyst saturates with moisture, it is no longer effectively breaking down ozone and requires regeneration or replacement. The heater has two effects on the ozone destruction process. The first is that warm air can hold more moisture and avoids the catalyst from getting moisture saturated. The second effect is that the warmer the air, the less stable the ozone molecule is and the easier it breaks down to oxygen.

Catalyst sieve

The core component of the ozone destruction system. Converts the ozone to oxygen.

Vacuum pump

When there is no positive pressure on the inlet of the catalyst sieve. The ozone-air mixture cannot move through the sieve because it requires force. The vacuum pump can suck the ozone air mixture through the sieve equipped with a flow controller and a flow indicator. So, it is easy to control the flow.