DO Controller Overview

Control on DO levels

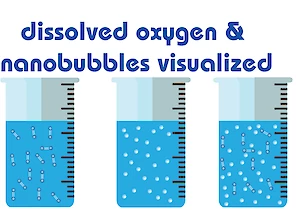

In the product line of control and monitoring, acniti delivers a DO controller and monitoring system. Acniti also offers a Nanobubble sensor system which approximates the bubble concentration in your process water. The controller and monitoring system is developed to work with any of our nanobubble generators and the oxiti oxygen concentrators. The DO controller is especially important for industries where too much of dissolved oxygen can do harm, for example in fish cultivation, shrimp and koi carps. The cost of energy in aeration applications is a big deal. Often aeration is the highest energy consumer, so running your systems fewer hours means savings, compared to using timers or do manual control.

Operate during set times

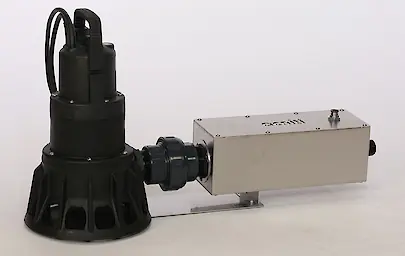

The DO controller consists of a DO sensor, a PLC a start stop output for the oxygen concentrator, a start stop output for a small pump if a larger pump in the setup is required a dry contact to start stop the pump is also available. In the DO controller set the DO value, below the set-point the Ultrafine bubble mixer will run until the set-point is achieved. In the PLC, you can set a delay interval of 2 minutes to 16 minutes between starting and stopping the ultrafine bubble mixer to avoid that it turns on and off frequently. The controller can also be used without a DO sensor, without a DO sensor there is a possibility to set a day program and run it in certain hours. The DO controller comes in a wall-mounted enclosure with a door of fiberglass reinforced, non-saturated polyester. Protection category IP 56 or IP 66. High stability thanks to use of fiber-glass reinforced plastic. The DO sensor is a membrane covered galvanic oxygen probe with built-in transmitter. The probe is connected to a DC supply and draws a current of between 4 and 20 mA corresponding to the oxygen concentration.

Monitor oxygen levels

For research and historic data, the DO controller can log data at a set interval time. The shortest interval is 1 second, the longest interval is over 2 hours. Transfer data easily to a USB flash drive by simply inserting the stick into the PLC. The unit has a capability of storing 10,000 measurement, when the maximum number of measurements is reached the oldest data entry will be overwritten.