Innovative Technologies for nanobubble generation

Making nanobubbles

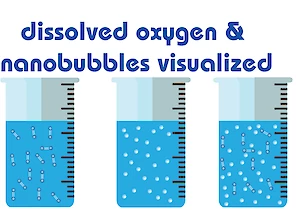

When making a bubble you put a gas into the liquid, a bubble is the family of a droplet which is a liquid in a gas. Another member of the bubble and droplet family is a particle, which is a solid in a gas or in a liquid. It's important to distinguish these three terms from each other for definition of Bubbles. There are a few methods to make bubbles, hydrodynamically, acoustic, optic and via particle cavitation. The most cost-effective method and most efficient method to make ultrafine bubbles is hydrodynamically. Hydrodynamics is a branch of physics that deals with motion on fluids and the forces acting on solid bodies immersed in fluids and in motion relative to them. To say it simple to create a bubble you need a moving liquid, add a gas and bring a force on the gas and liquid and the bubbles are created. In everyday life when you open a can of beer or a bottle of coke, by the change in pressure (the force) the bubbles are created, this is visible by the eye and by the sound.

1982 was the first time to publish an article about nanobubbles and until recently the existence of nanobubbles was heavily debated, the recent hype in ultrafine bubble technology or nanobubble technology is caused by two factors, first, there is now equipment on the market available that can measure ultrafine bubbles size and density and now most of the scientists agree that nanobubbles exist. Second, the big advantage of the measuring equipment was that ultrafine bubble makers are now able to further develop and optimize their ultrafine bubble generators, and they further develop applications.

Basically, there are two types of nanobubble generation technologies, first there are gas-water circulation types of nanobubble generators. Second there is a gas-water pressurization-decompression also often referred to as pressurized dissolution type of nanobubble generator. Most units are based on one principle or the other, or a combination of both.

We can distinguish the following production methods of fine bubbles; the first 5 methods are described in more detail:

- Pressurized dissolution

- Rotational Flow

- Turbulent Static mixer

- Ejector Nozzle

- Hammermill Rotation

- Ultrasonic (Supersonic vibration)

- Oscillator

- Venturi

- Mixed vapor direct contact condensation

Pressurized dissolution method

The Pressurized dissolution method of ultrafine bubble generation is based on the principles of Henry's Law, which relates the concentration of a gas to the partial pressure. This means that more gas can be dissolved into a solution at a higher pressure. The principle of the ultrafine bubble generator is as follows: Via a venturi system the liquid and the gas are mixed together, in the next step in the mixing box the gas is melted into the water via pressurization. In the last step via a nozzle the water and gas is discharged. Due to drastic drop in pressure of the supersaturated liquid gas solution, the gas is expelled as fine bubbles and ultrafine bubbles in the liquid. The figure illustrates the process.

- Liquid is pumped into the unit under pressure.

- By narrowing the size of the pipe, the speed of the incoming liquid flow is increased, which converts most of the pump pressure into dynamic pressure, thus reducing static pressure and air being suctioned through negative pressure.

- After the liquid and suctioned gas become saturated with bubbles, the liquid/gas flow is sent through a wider pipe to reduce the speed of the flow, where dynamic pressure is converted back to static pressure and the process of pressurized dissolution of gas takes place.

- After the gas is completely dissolved into the liquid, the liquid/gas is ejected at once using atmospheric pressure, causing the liquid to become over-saturated, and massive ultra fine nanobubbles are released.

Rotational flow

Rotational flow is also often called Swirl Method or Spiral Flow. This fine bubble generator generates bubbles according to the Bernoulli's principle. In fluid dynamics, Bernoulli's principle states that an increase in the speed of a fluid occurs simultaneously with a decrease in pressure or a decrease in the fluid's potential energy. The principle is named after Daniel Bernoulli, who published it in his book "Hydrodynamica" in 1738. Centuries later, fine bubble generators are made based on this principle. The first product based on this technology is the Ranque-Hilsch Vortex Tube in 1933. Followed 50 years later by the Swirling jet flame. In the mid-nineties, the first swirling type micro-bubbles was invented in Japan.

The principle of the fine bubble generator is as follows: water is put into a cylindrical tank from the top-side and made to flow in a spiral downwards. From the center bottom of the cylinder, the gas is sucked in. The rotating water is sheared to the top of the cylinder, producing fine bubbles. However, it's generally acknowledged in the ultrafine bubble industry that the bubble concentration of the pressurized dissolution method is higher than the rotational flow.

Turbulent Static Mixer

The static mixer has its origin from mixing two liquids, the first patent for a static mixer was filed in 1965. Instead of mixing two liquids, there is also the possibility of mixing a liquid and a gas. This technology is based on the principle of creating a vortex and bringing into the vortex a gas very effectively. Due to the turbulent flow gas will break the vortex and the collisions between water and gas creates the nanobubbles. The benefits of the static mixers are that they have a relative simple design, and they can treat large volumes of water at once with relative little energy compared to many of the other above nanobubble generators. Finally, they are not sensitive to clogging. The acniti Turbiti technology is a combination of the turbulent static mixer and the Ejector Nozzle.

Ejector Nozzle

In the ejector nozzle nanobubble generator type, liquid flow channels in the cylindrical generator are designed to shrink and stepwise enlarge. The gas is brought in under negative pressure at the most reduced pressure point and reduced to a number of nanobubbles by cavitation. In this device, the water flow is highly turbulent, and the gas is reduced to nanobubbles by cavitation. Ejector nozzles are closely related to hydrodynamic cavitation generators, with this method cavitation is generated by the flow of liquid through a simple geometry under controlled conditions. In this nanobubble generator, when the pressure falls below the vapor pressure of the liquid, the liquid flashes, generating a number of cavities. The cavities collapse when the pressure recovers. The collapse of the cavitation bubbles starts some physicochemical effects such as shock waves, shear forces and chemical reactions. Free radicals are sometimes generated by the these processes.

Hammermill Rotation

The hammermill rotation concept is a unique concept compared to all the other nanobubble generation techniques, as it does not use a pump to generate nanobubbles. Instead, it uses a motor with hammers mounted on the shaft. The motor turns at a velocity of 3400 rotations per minute in a tube. The tube fills with water from the top, and the gas injection is also from the top. The hammers on the shaft dissolve the gas and crushes the gas into nanobubble at the bottom of the unit the nanobubbles come out. The hammer rotation concept is the most energy-friendly way to generate nanobubbles as it does not move large amounts of water and doesn’t need high pressure, but uses all its energy to crush the gas. The lineup of hammermill rotation nanobubble generators is called the microStar nanobubble generator. This unit is suitable for ozone gas and for use in seawater environments.